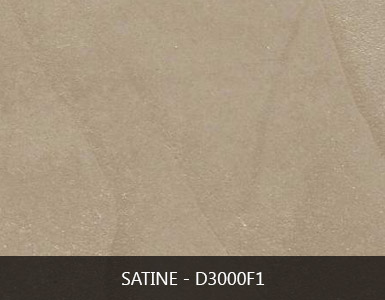

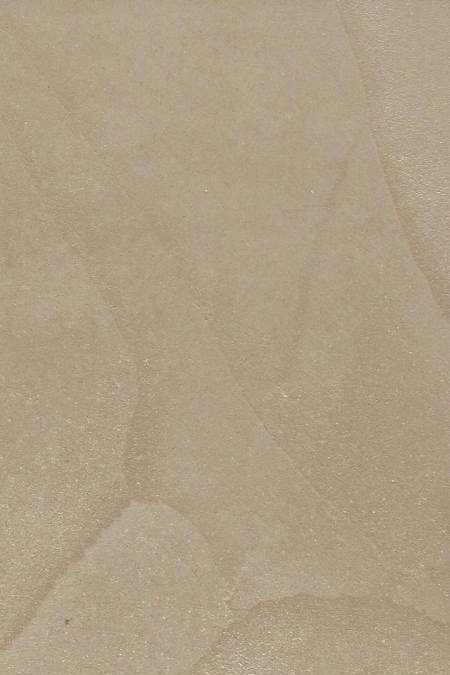

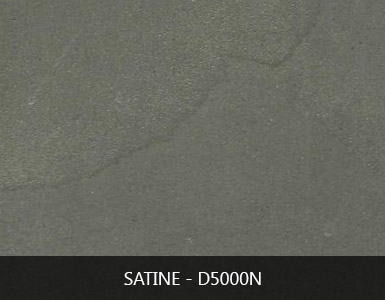

Forged Cement

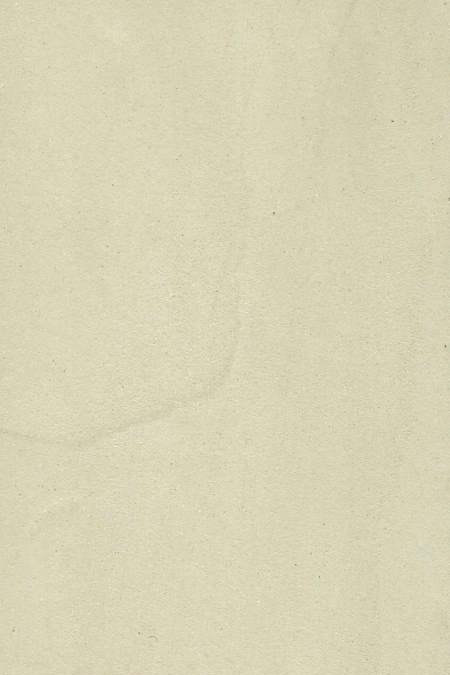

The cement we knew until today as a floor base before laying tiles or wood. However, in recent years we have seen the most exeligmeni and perfected form a colored applications indoors and outdoors. The art of trowelled screed is a modern construction method is found in walls, interior and exterior floors, built-in benches as well and the sanitary facilities.

The forged cement is an ecological and natural material which has excellent strength and is completely waterproof. Through the application of a created surface without cracks or cracks, while ensuring the most excellent traction in high mechanical strength, but also in coatings for heating through the floor. Additionally, the correct spreading of the cement with a specific varnish may apofechthoun spots on the surface from dirt, oil or moisture.

Advantages of forged cement

- Small application thickness rarely exceeds 3 – 4 mm on the floor and 2 mm on the walls, so there is great interest in reconstructions.

- Adhesion to existing coatings directly on tiles, wood and dry wall, mosaics, cast iron sanitary ware and furniture.

- High strength in areas such as heavy duty floors, stairs, bathrooms, wc and sanitary surfaces (restaurants – Cook).

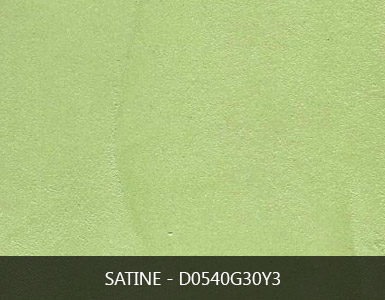

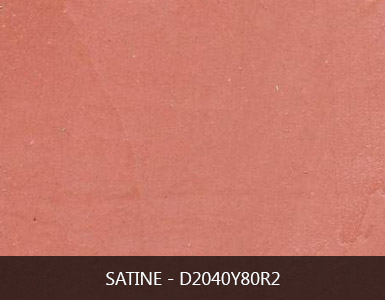

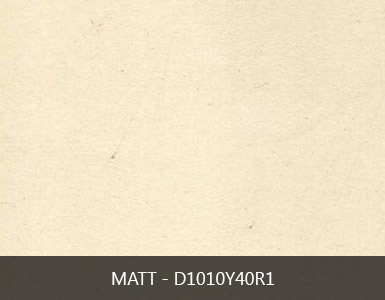

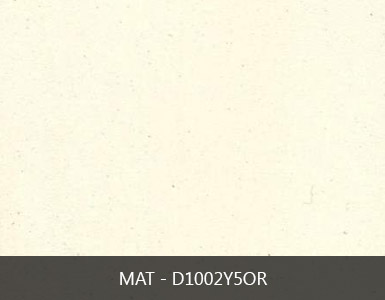

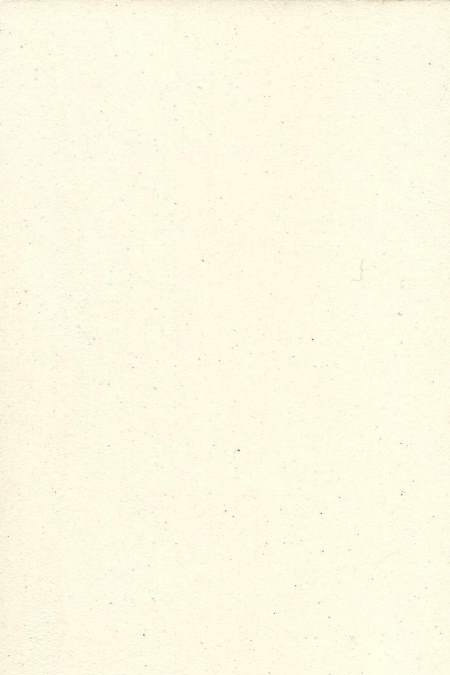

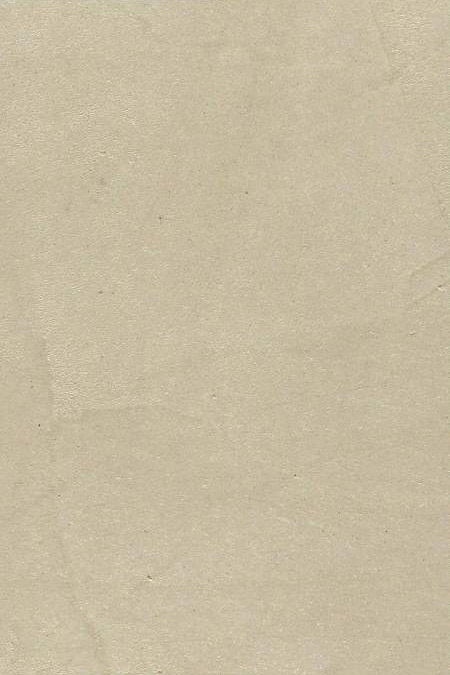

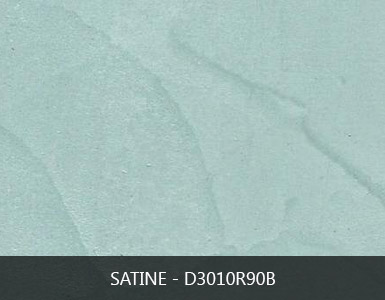

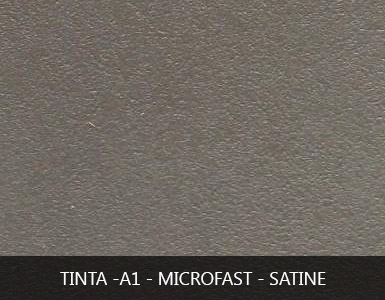

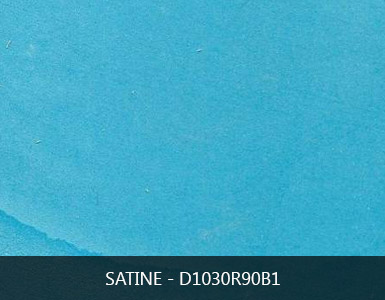

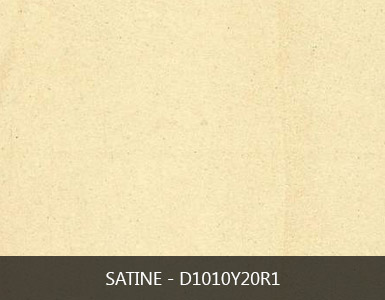

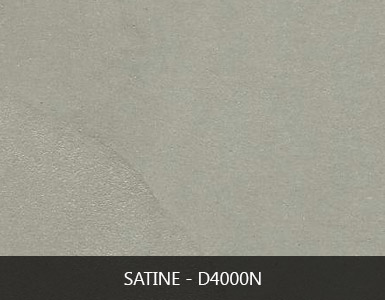

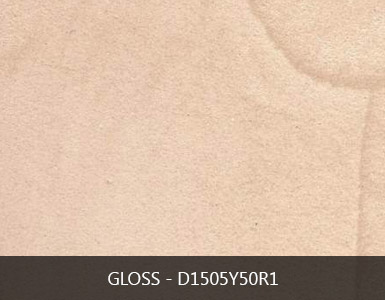

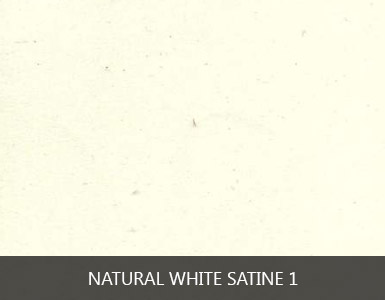

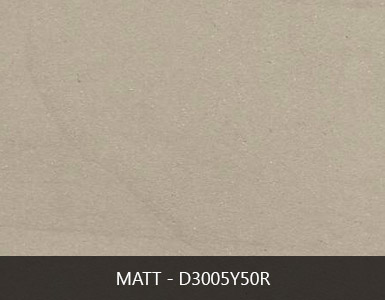

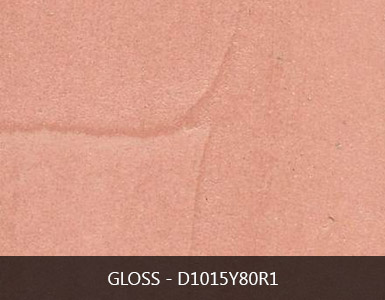

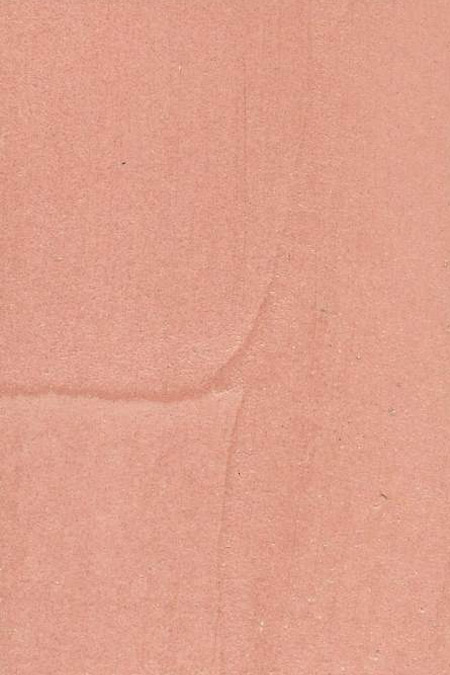

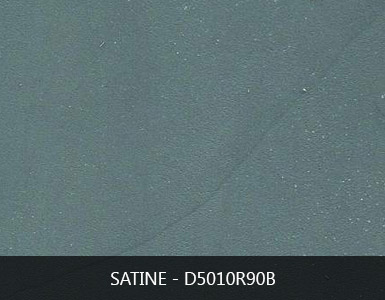

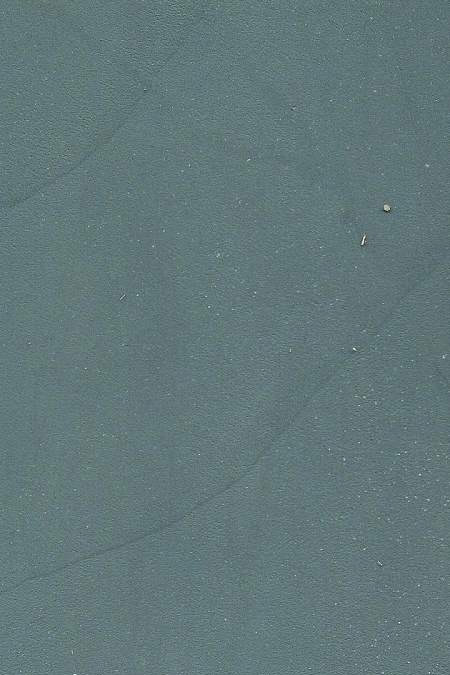

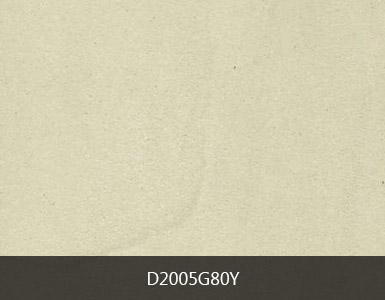

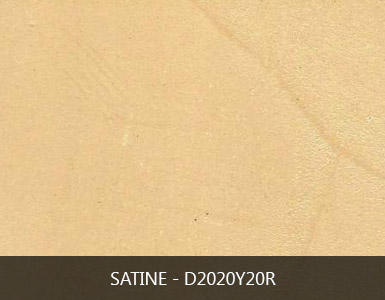

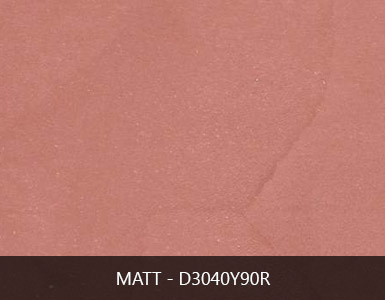

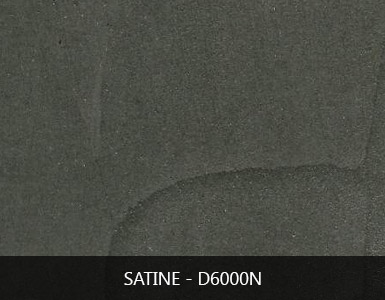

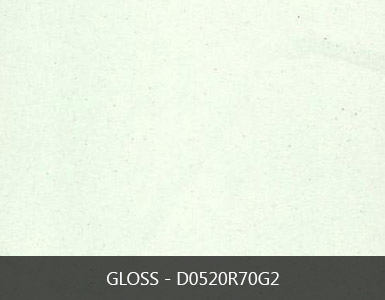

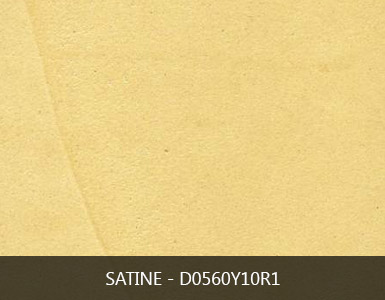

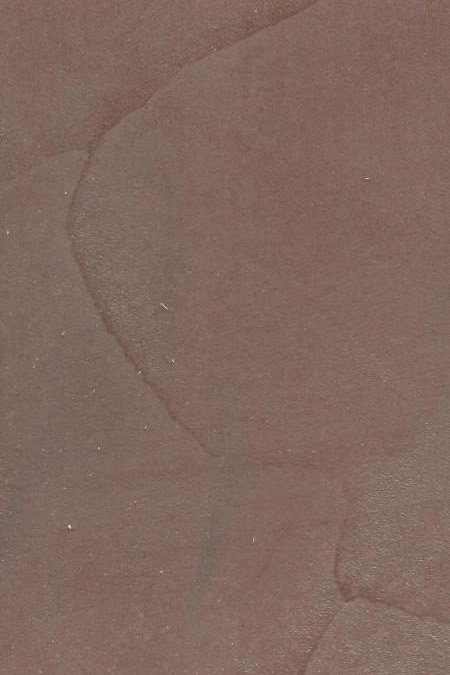

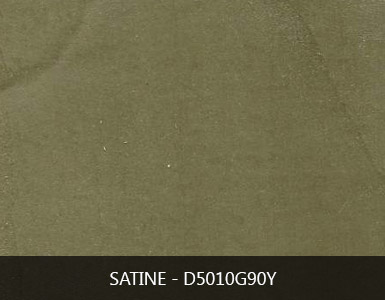

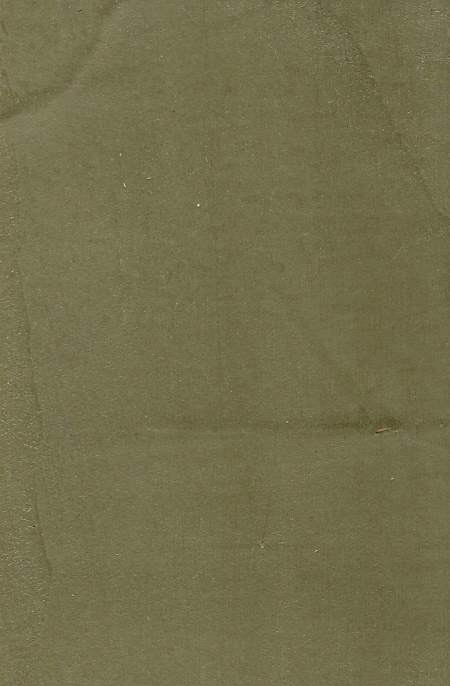

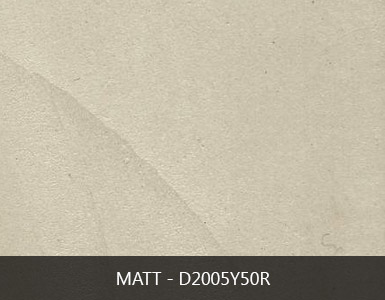

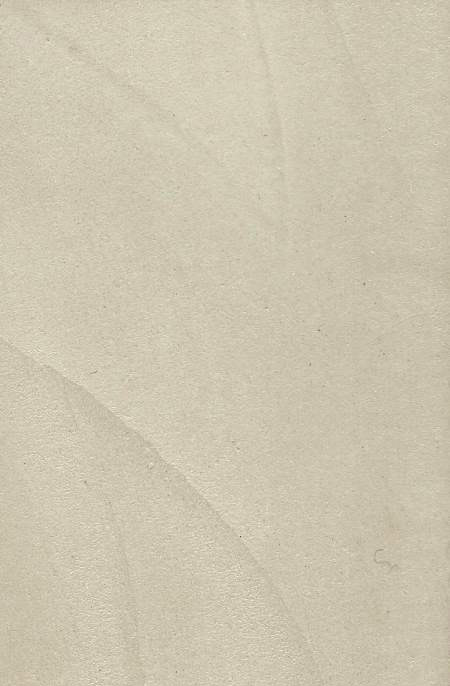

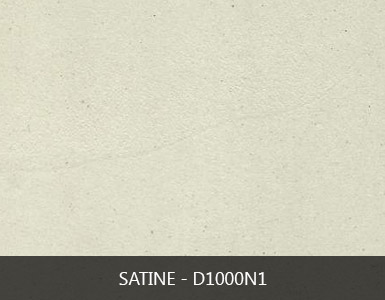

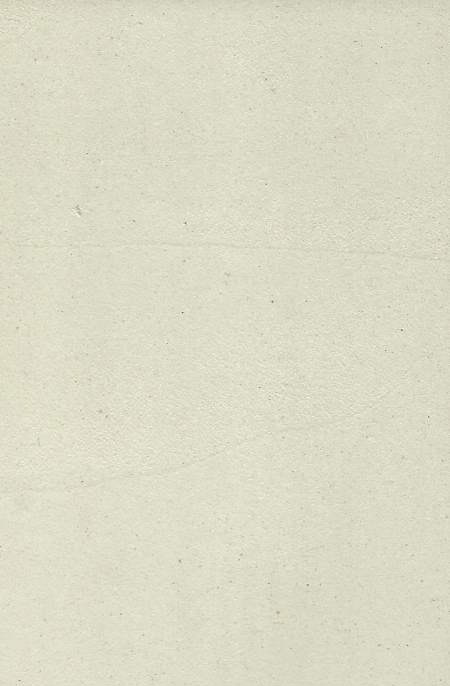

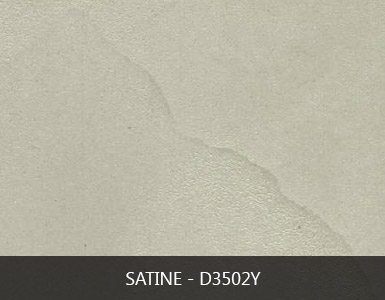

- Available in a variety of RAL colors.

- Suitable for indoor – outdoor areas, swimming pools, underfloor heating, furniture.

- Each application, depending on the area, protected by high-strength varnish long time.

- Forged cement with special anti-scratch properties, high resistance to chemicals and stains, high elasticity (3.5 N / mm²) high impact resistance (32 N / mm²), ideal for underfloor heating.

- Applied directly onto tiles, mosaics, with a maximum thickness of 5 mm, with special abrasion resistant varnish water, two components in matt, satin and gloss resistance to chemicals (UNI EN ISO 2812-1 method 2) and abrasion resistance (> 3.0 N / mm²).